LUBRICATION 101: A LOOK AT BASIC LUBRICATION CONCEPTS

Lubrication can be a daunting subject for someone unfamiliar with its basic concepts. Even someone with experience in the field can be confused by the multitude of lubricants available on the market today. Reviewing a few basic lubrication principles can make it easier to understand why proper lubrication is necessary in every application.

FRICTION

Webster defines friction as the “rubbing of one body against another,” and as “resistance to relative motion between two bodies in contact.” Friction can be beneficial. It generates heat that can be used to start a fire, and it is the principle behind a vehicle’s braking system.

Friction can also be detrimental. The heat generated as the result of friction can cause damage to an engine. Because contact is required to generate friction, wear can take place in these areas of contact, leading to material failures, overheating and the formation of deposits. Although there are many ways to reduce friction, the most common way is through the use of a fluid or semifluid lubricant. The key characteristic of lubricants is that they are not readily compressible, minimizing component contact or eliminating contact altogether.

TYPES OF LUBRICATION

There are three types of lubrication conditions that can exist between two surfaces:

Hydrodynamic or

Full-Film Lubrication is the condition in which surfaces are completely separated by a continuous film of lubricating fluid. The non-compressible nature of this film separates the surfaces and prevents metal-to-metal contact. The lubricant’s viscosity assumes responsibility for the majority of wear protection; additives play a limited role. Although full-film lubrication does not generally allow metal-to-metal contact, abrasive wear or scratching can still occur if dirt particles penetrate the lubricating film.

HYDRODYNAMIC LUBRICATION

SURFACES SEPARATED BY BULK LUBRICANT FILM

Engine components operating under a full-film lubrication regime include the crankshaft, camshaft and connecting rod bearings, and piston pin bushings. Under normal loads, transmission and rear-axle bearings also operate under a full-film regime.

Elasto-Hydrodynamic Lubrication exists when a sudden reduction of the oil film causes a temporary increase in viscosity. When viscosity increases, the film can become rigid, creating a temporary elastic deformation of the surfaces. The lubricant’s viscosity and additives work together to protect surfaces in an elasto-hydrodynamic regime.

The shear strength of the fluid increases due to an increase in load or pressure of a surface and behaves as though it were stronger than the metal surface it acts against, thus causing the surface to deform.

Anti-wear additives are often relied upon to protect engine bearings in high-load conditions, while both anti-wear and extreme-pressure additives work to protect gears in high-load conditions.

BOUNDARY LUBRICATION

PERFORMANCE ESSENTIALLY DEPENDENT ON BOUNDARY FILM

Boundary Lubrication is a condition in which the lubricant film becomes too thin to provide total surface separation. This may be due to excessive loading, low speeds or a change in the fluid’s characteristics. In such cases, occasional metal-to-metal contact takes place between surfaces, and the surfaces are almost entirely dependent on the lubricant’s additives to provide protection.

Anti-wear additives protect the cam lobes, cylinder walls and piston rings in engine high-load conditions, while antiwear and extreme-pressure additives protect ring and pinion gears in rear axles.

OTHER LUBRICANT FUNCTIONS

Though minimizing friction and wear is the primary function of a lubricant, it is also required to perform the following tasks:

Clean - A lubricant must maintain internal cleanliness by suspending contaminants or keeping contaminants from adhering to components.

Cool Moving Elements - Reducing friction minimizes the amount of heat generated and lowers the operating temperature of the components. A lubricant must also absorb heat from the components and transport it to a location where it can be safely dissipated.

Prevent Contamination - The lubricant must act as a dynamic seal in locations such as the piston, piston ring and cylinder contact areas. This minimizes contamination by combustion byproducts, for example, in the lubricating system. Lubricants are also relied upon to support mechanical seals found elsewhere and to minimize external contamination and fluid loss.

Dampen Shock - The lubricant may be required to cushion the blows of mechanical shock. A lubricant film can absorb and disperse these energy spikes over a broader contact area.

Transfer Energy - A lubricant may be required to act as an energy transfer medium as in the case of hydraulic equipment or lifters in an automotive engine.

Prevent Corrosion - A lubricant must have the ability to prevent or minimize internal component corrosion. This can be accomplished either by chemically neutralizing the corrosive products or by setting up a barrier between the components and the corrosive material.

COMPONENTS OF A LUBRICANT

Lubricants are generally composed of two groups of materials. Base oils comprise 75 to 95 percent of the finished product. The most commonly used base oils are derived from petroleum crude oil. Additives are usually added to the base oils to enhance or impart new properties. The use of such special chemical compounds is another way to minimize friction and wear, and they can offer protection when the lubricating fluid cannot maintain component separation.

INCREASED DEMAND ON LUBRICANTS

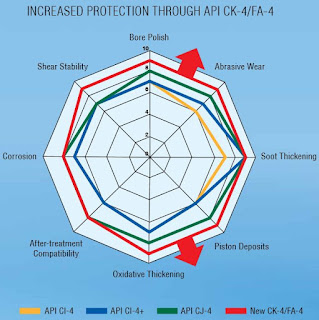

As time goes on, the lubrication needs of equipment continue to change. As equipment becomes more advanced and sophisticated, the demands placed upon the required lubricants become more severe. What may have been a preferred lubricant in the past is likely to be totally unacceptable today.

The automotive industry is an excellent example of how demands on equipment have changed. The engines used in today’s vehicles require significantly more from a motor oil than they did in the past.

Modern vehicles are requiring lighter viscosity oils for improved fuel economy, but feature engines that output more power per cubic inch of displacement than ever before. To achieve this power level, vehicle manufacturers are adding turbochargers that expose motor oils to higher temperatures and greater stress. Meanwhile, requirements for cleaner exhaust emissions have contributed to higher levels of contaminants in the oil and increased the oil’s operating temperature. By reducing aerodynamic drag, manufacturers have also minimized the amount of air that flows over engines and drivetrains, causing operating temperatures to trend further upward. Even with all these changes, manufacturers are requiring lubricants to last longer than they ever did before.

HOW ARE SYNTHETIC OILS DIFFERENT?

Although the engineering of synthetic base oils varies, synthetics are generally made through a reaction process that significantly improves the consistency of the base oil and its molecular uniformity. Conventional petroleum base oils, on the other hand, are obtained through a process of distillation.

Distillation slightly limits the molecular diversity that may exist within the base oil, but does not completely eliminate nonessential molecular structures. This is important because unnecessary molecular structures produce variations in the base oil’s performance. The ideal lubricant’s chemical composition is one in which the molecular construction is identical throughout, such as in a synthetic base oil. Because of the way synthetic base oils are produced, they are molecularly uniform and contain significantly less undesirable materials than a conventional base oil.

Molecular uniformity also affects the properties that each type of lubricant possesses. The properties of conventional oils tend to vary due to inconsistencies in the crude oil from which they are obtained. The properties and performance features of synthetics, on the other hand, are predictable due to their molecular uniformity.

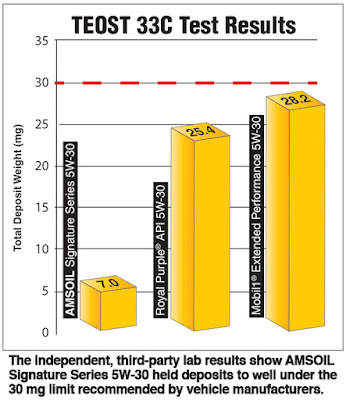

AMSOIL synthetic lubricants are formulated to take advantage of the superior properties of premium synthetic base oils and top-of-the-line additives. They provide excellent lubrication and wear protection and have been designed to resist the chemical breakdown processes that limit the service life of conventional petroleum oils.