What Your Motor Oil Color Means

John BakerJohn Baker | Jan 09, 2020 8:54 AMAn object’s color can reveal a lot about its condition. A brown apple? Probably not great to eat. A slice of green bread? Same. What about motor oil color? Can your eyes provide insight into your oil’s suitability to protect your engine?

Does motor oil that’s turned black require changing?

Not necessarily. In this case, the oil’s color is a sign it’s doing its job.Oil naturally darkens during use for a couple reasons, including heat cycles. During your drive to work, your engine reaches normal operating temperature (typically 195ºF–220ºF [90ºC–104ºC]), heating the motor oil.

Then the oil cools while your car sits in the parking lot. The process repeats as you run errands over lunch and when you return home.

This continual daily exposure to increased heat naturally darkens the oil.

In addition, normal oxidation can darken oil.Oxidation occurs when oxygen molecules interact with oil molecules and cause chemical breakdown, just like how oxygen causes a cut apple to brown or iron to rust.

Soot also causes oil to turn black.

While we associate soot with diesels, today’s direct-injected gasoline engines can produce more soot than older diesels without exhaust-treatment devices. While individual soot particles are too small to cause engine wear, particles can agglomerate into larger wear-causing contaminants that can lead to wear before they lodge in the oil filter.

Just because the oil has darkened doesn’t necessarily mean it’s reached the end of its service life.

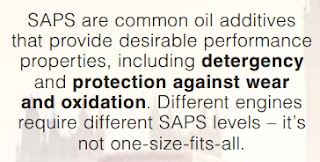

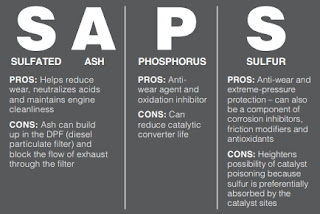

Motor oil contains detergent and dispersant additives designed to clean contaminants like soot and prevent them from depositing onto metal surfaces.Oil that has turned black is an indication the additives are doing their job. You can read more about that here.

What about motor oil that looks like chocolate milk?

In this case, motor oil color does reflect performance…and oil that looks like chocolate milk is bad. Very bad.Water or engine coolant have contaminated the oil, typically due to a head gasket leak.

We all know that water and oil don’t mix. When they combine in your engine, water droplets suspend in the oil and alter its appearance until it looks frothy or like chocolate milk.The presence of water leads to foam bubbles, which rupture when pulled between engine parts during operation, leaving metal components unprotected against wear.

It also forms sludge, which can clog oil passages and ruin the engine. In this case, see a mechanic as soon as possible.

What if my oil looks or feels thin?

While not related to motor oil color, this is another frequent question we field from motorists.Don’t take this the wrong way, but in this case go out to the garage and smell your dipstick.

Oil that has lost viscosity is often due to fuel dilution. You can usually smell gasoline or diesel fuel on the dipstick in such cases.

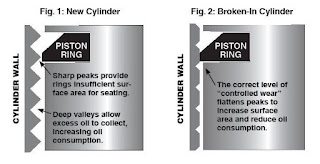

Fuel dilution occurs when gas or diesel wash past the piston rings and contaminate the oil in the sump. It reduces oil viscosity, which reduces the oil’s ability to prevent wear. It also leads to formation of harmful varnish and sludge.Fuel dilution can occur if you idle your engine excessively or due to a mechanical defect. It’s also common in some modern direct-injected engines.

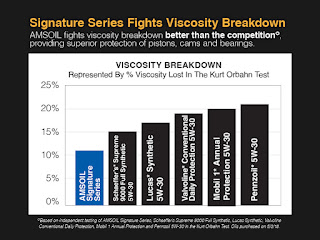

It’s important to note that no one can precisely measure an oil’s viscosity simply by looking at it or rubbing a little between their fingers.

As Oil ANALYZERS INC. manager Allen Bender likes to ask, “When’s the last time you had your eyes calibrated?”Oil analysis in the only definitive way to determine the oil’s viscosity and whether it’s lost viscosity due to fuel dilution.

My oil feels gritty? Should I change it?

When checking oil level, some motorists like to rub oil between their fingers to check for particles.Grit or other contaminants can mean the oil has chemically broken down, but this is unlikely, especially with a top-shelf synthetic oil.

More likely, the oil filter has filled with contaminants and unfiltered oil is bypassing the filter and circulating through the engine.

The filter is designed with a bypass valve to ensure the engine receives oil even if the filter is full.While dirty oil is preferable to no oil, it’s not a long-term plan for success. In this case, change the oil and filter.

Trust oil analysis, not your eyes

While it’s possible to get a rough idea what’s going on inside your engine due to oil color, appearance or scent, you need to perform oil analysis to find out what’s really going on.By chemically analyzing a used-oil sample, a qualified lab can tell you if the oil contains excessive wear particles, water contamination, fuel dilution and more. Ultimately, the report will tell you if the oil is suitable for continued use or not.

It’s a cost-effective way to get the most out of your oil change…and your engine. Check out this post to see how to perform oil analysis.